About Us

Huizhou foryou Intelligent Technology Co., Ltd. is a wholly-owned subsidiary of Huizhou foryou Multimedia Electronics Co., Ltd.

SINCE 2008

Foryou Automation Division was established in 2008, which is subordinate to Huizhou Foryou Multimedia Electronics Co., Ltd. After years of development, it had became an independent company in 2021, which is called Foryou Intelligent . We dedicate ourself to provide intelligent factory solutions in the manufacture field of Lithium cells PACK、PCM of smart phone and anyother 3C products just like small household appliances.

Company strength

Professionals:The proportion of technical R&D personnel is more than 45%, and the proportion of senior personnel with more than 5 years of industry experience is more than 30%;

The company has established a joint postgraduate training base with colleges and universities, and employed experts and professors as technical consultants to strengthen R & D and promote the transformation of scientific and technological achievements.

The ability to carry out more than 10 complete line automation projects at the same time, and the annual delivery capacity of equipment exceeds 1,000.

Recommended Products

We dedicate ourself to provide production and logistics automation solutions for customer, focusing on automatic manufacturing of battery PACK、PCM and consumer electronics .We are good at applying and integrating such as robot、industrial vision、AGV、stereoscopic storage、ATE and MES.

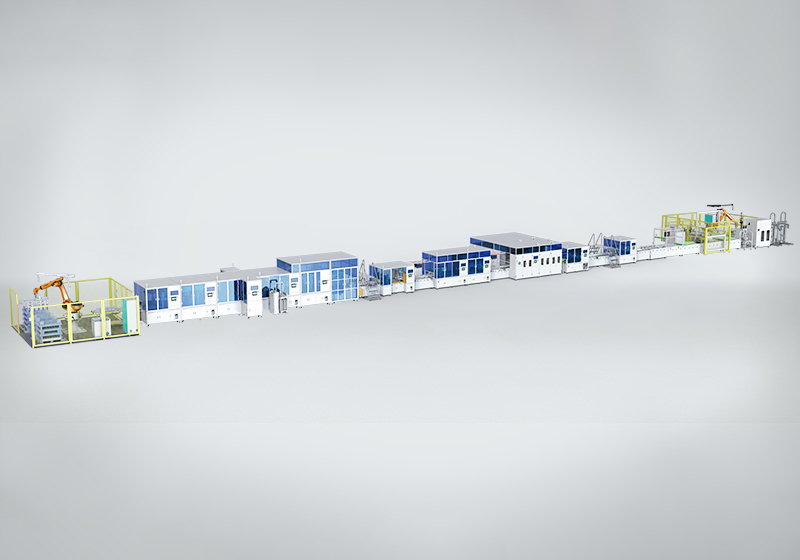

Square aluminum shell module PACK automatic line

It is suitable for the module pack production of square shell cells, and the functions include: cell feeding, OCV testing, cell surface cleaning, automatic glue (sheets, strips) automatic stacking, pole cleaning, polarity detection, laser welding, post-welding detection, automatic boxing, pack box dispensing, etc.

Mini Automatic Line for Cylindrical cell

The product is suitable for the front section of the cylindrical battery PACK line and is compatible with conventional cylindrical batteries such as 18650/20650/21700. The function of the whole line includes automatic sorting, automatic support, automatic installation of battery connecting pieces, automatic spot welding (resistance welding), etc.

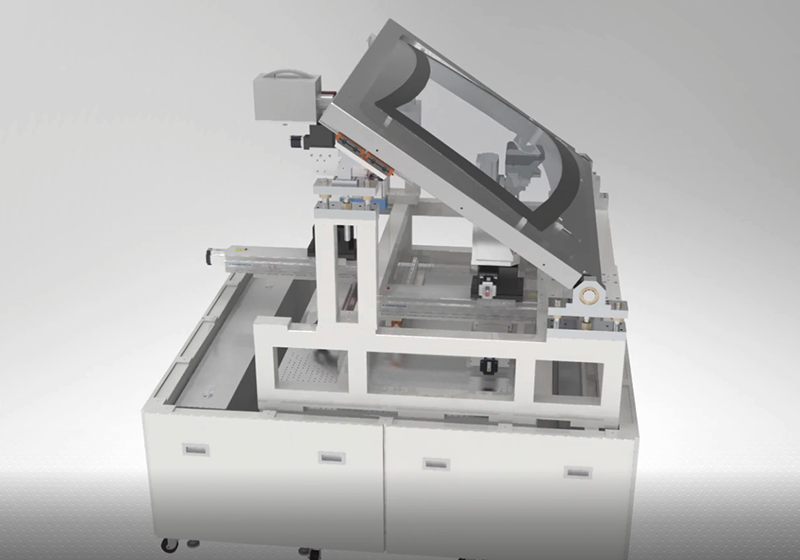

PCM Loader

It's used to do the PCM automatic loading, the automation process include: PCM in tray stack loading , CCD positioning, PCM mounting by SCARA, code (on fixture) scanning, fixture positioning by Mark recognition, etc. The fixtures designed to move in on the upper belt conveyor and reflow from the bottom one, so the efficiency loss by fixture waiting can be significant reduced and the equipment OEE will be greatly improvement.

Automatic line for Electric Tools' PACK

It is suitable for automatic production of electric tools PACK (within 20 cells in one PACK). The automation process include: cells loading and sorting, cells insert into housing, connector assembly, spot welding, PCBA installation and fixing , glue dispensing, soldering, naked pack test, case assembly, labeling and laser carving, final test , etc.

Automatic assembly line for Car Wireless Charging

It's a semi-automatic line for the Car Wireless Charging manufacturing , the automation process include : screwing, glue dispensing, pressure holding test , soldering, function test, FOD test, etc.

Automatic assembly line for HUD

It's a semi-automatic line for the HUD manufacturing , the automation process include : screwing, glue dispensing, pressure holding test , vibration test, function test, image test , etc.

Auto vision inspection equipment for HUD

It's used to do the HUD optical performance test through simulating the different positions and angles when the HUD installed in a vehicle. A multi-axises motion mechanism was designed to realize simulation of the HUD installation , and a binocular camera was used to simulated human eye recognition , CPU comprehensive calculation of the data collected by the camera to determine whether the product meets the quality requirements. It is designed to be compatible with many vehicle models .

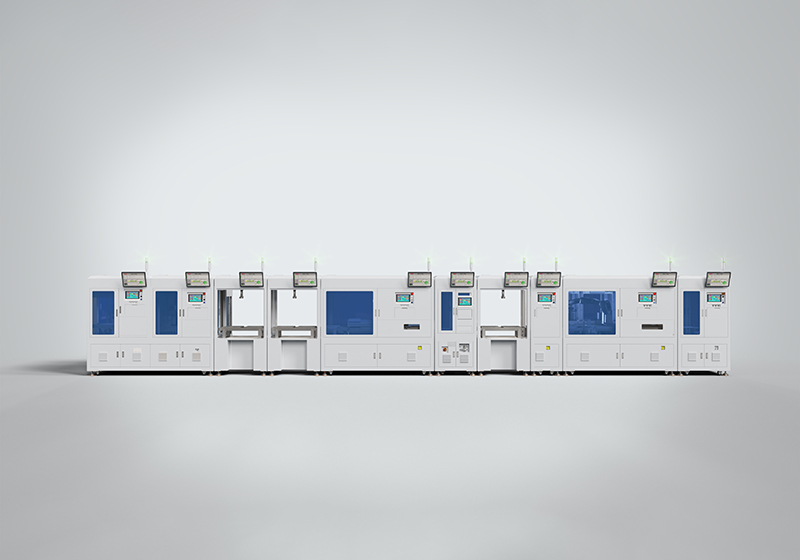

Automatic line for PCM Used in Notebook

It's used to produce battery protection board of notebook, the automation process include: PCBA splitting, PCBA mounting ,wiring harness &NTC fixing, pressure soldering, etc. A multi-position code scanning solution was designed to ensure a 100% successful barcode recognition to realize info traceability .

News

Technology Creates Quality Life

ADD:Address: Building 4, Zone B, Foryou Industrial Park, No. 1, Shangxia North Road, Dongjiang High-tech Industrial Park, Huizhou City, Guangdong Province

TEL:0752-5300866

FAX: 0752-5300666

E_mail : sales-fa@adayome.com

Website : www.adayo-automation.com

版权所有 © 2021 Huizhou foryou Multimedia Electronics Co., Ltd. 粤ICP备2021038359号

Pwower by:www.300.cn

0752-5300866

0752-5300866

在线留言

在线留言